Dry Ice Energy

Dry Ice Energy is the inventor of compact and easy-to-use dry ice blasting devices. Cleaning with dry ice is significantly faster and easier than with conventional methods and works without water. Dry Ice Energy’s patented and uniquely handy cleaning machines finally makes the advantages of dry ice cleaning easy to use and uncomplicated.

ADvantages of dry ice cleaning

Top cleaning results even in hard-to-reach areas

Free from harsh cleaning chemicals

Water-free cleaning, no wasted time waiting for surfaces to dry

Gentler than conventional cleaning methods

Wide range of applications across multiple industries

How Dry Ice Cleaning works

1.

Pellets of dry ice (CO 2) are fired at the surface at high speed

2.

As the pellets hit the surface, they sublimate almost immediately, turning into a harmless gas that doesn’t inflict damage to the surface

3.

Contaminants such as dirt, dust and debris become brittle, flaking away from the surface

4.

After the CO 2 gas expands and removes contaminants, a clean surface is left behind. Dry ice cleaning is gentle and doesn’t create additional mess to clean up afterwards

Applications

- INDUSTRIAL MACHINE MAINTENANCE

- PLASTICS INDUSTRY

- HEALTH & REHABILITATION

- CATERING

- AUTOMOTIVE

- OTHER VEHICLES

Simplify machine maintenance and significantly reduce cleaning times with Dry Ice Energy. Dry ice cleaning is ideal for maintaining ventilation systems, machines, and control panels.

Dry ice cleaning blasts away dust, grease, oil, mould, and bacteria from sensitive electrical components, ensuring thorough cleaning, all without the use of water or chemicals.

Dry Ice Energy is revolutionising the mould cleaning process in the plastics industry. A smooth, clean mould surface is important for maintaining uniformity and reducing defects. With the incorrect cleaning methods, moulds become scratched and misshapen.

Dry ice cleaning is gentle on moulds, extending their lifecycle. It effectively reaches tight spaces and allows for cleaning during ongoing operations, eliminating downtime.

In the health industry where sanitisation is crucial, dry ice cleaning is perfect for maintaining essential aids like wheelchairs, nursing beds, and other medical equipment. It removes dirt and bacteria. ensuring that equipment is hygienic and safe.

Additionally, the lack of water or chemicals means there are no downtimes for drying, allowing for continuous use of the equipment. This allows health professionals to better service those in need.

Another area where hygiene is incredibly important is the food industry. Dry ice cleaning removes germs as well as stubborn oils and fats from catering equipment without using harsh chemicals.

It provides a hygienic, food-safe, and mess-free solution that maintains high standards of cleanliness and safety.

Thanks to the innovative design of Dry Ice Energy machines, dry ice cleaning can be efficiently applied to car interiors, engine bays, and electrical components, reducing cleaning time by 25-40%.

This method is not only faster but also gentler and more environmentally friendly than traditional cleaning, as it eliminates the need for water and harmful chemicals.

Dry ice cleaning offers significant advantages for the delicate and hard-to-reach components found on planes, motorbikes, and bicycles/e-bikes. This method excels at cleaning intricate and sensitive areas that are challenging to access with traditional methods.

Dry ice cleaning’s precision and non-abrasive nature make it ideal for maintaining the performance and longevity of these complex and valuable machines.

The Dry Ice Energy DIfference

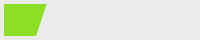

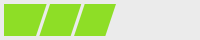

Unlike other models that are heavy, noisy, complicated and costly to own and operate, Dry Ice Energy machines stand out with their German-engineered design. They are compact, powerful, and incredibly user-friendly, making dry ice cleaning simple and accessible.

With these machines, starting your own mobile service business becomes more achievable than ever. Oz-Gel proudly supplies Dry Ice Energy machines to the Australian market. If you’re interested in any of our machines, or have any further questions, contact us today!